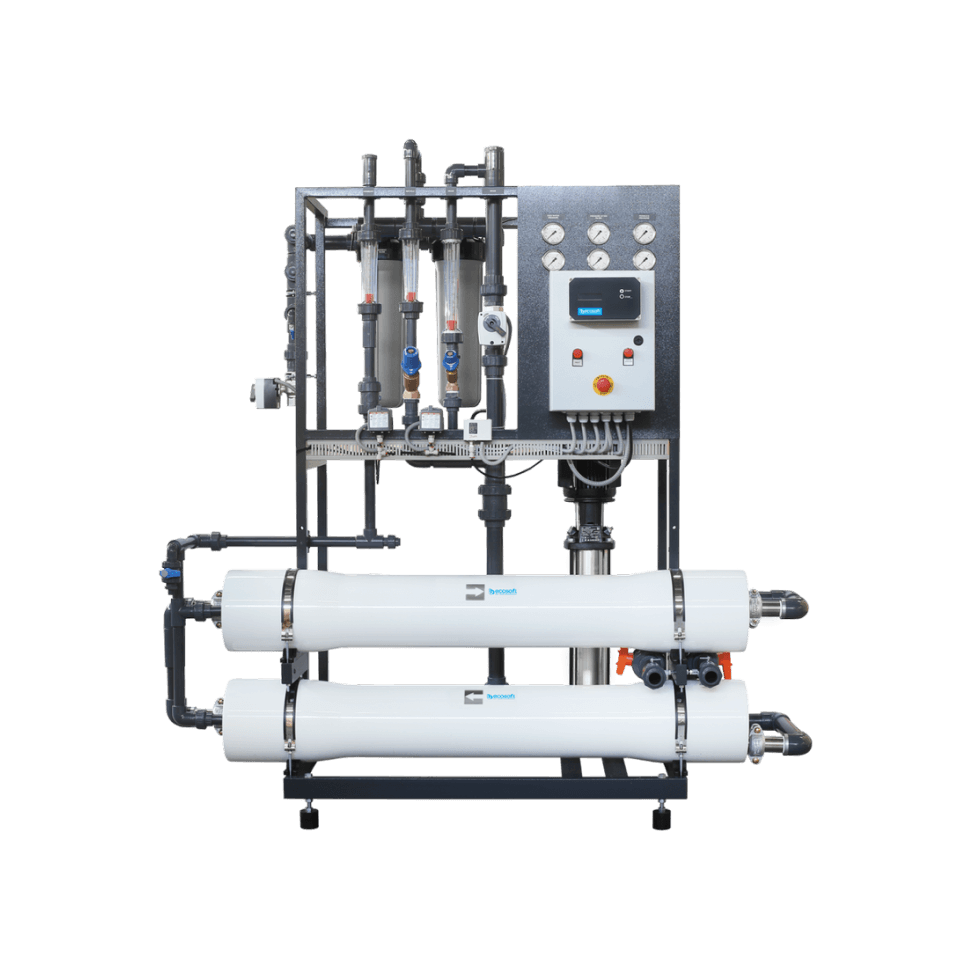

Ecosoft MO2 industrial reverse osmosis system is a turnkey solution for industrial water challenges, that includes pilot studies, engineering and manufacturing, commissioning and maintenance.

Ecosoft reverse osmosis systems are used in food and pharmaceutical industry, energy, chemical, semiconductor manufacturing, steam boilers and other industrial applications.